What Are the Best Thermal Interface Materials

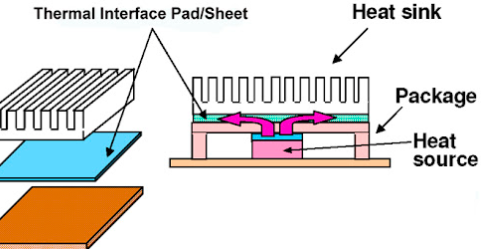

Keeping electronic devices cool and working efficiently depends on choosing the right Thermal Interface Materials (TIM). TIMs help move heat from components to their cooling systems, preventing overheating and ensuring devices last longer. Choosing the right TIM is tricky due to differences in heat transfer, ease of use, and durability. This article reviews the top TIMs and explains their best applications.

Key Criteria for a Top-Tier Thermal Interface Material (TIM)

- High Thermal Conductivity & Low Thermal Resistance

Moves heat efficiently between components, keeping temperatures lower. This is vital in high-power electronics.

- Good choices: Graphene-based composites, metal-filled pastes, sintered silver, and indium alloys.

- Good Conformability & Gap-Filling Capability

Air gaps act as heat blockers. A good TIM fills in tiny surface imperfections to improve contact.

- Good choices: Good TIMs include thermal grease, PCMs, and soft pads that adapt to surfaces.

- Tip: Pad performance depends on how much they’re compressed.

- Electrical (In)Sulation as Needed

Choose a TIM that insulates or conducts based on your device’s electrical requirements.

Good choices:

- For insulation: For electrical insulation, use ceramic fillers such as boron nitride.

- For conductivity: Specially designed conductive materials.

- Durability & Stability Over Time

TIMs should be durable and stable, resisting heat and aging to maintain performance.

- Good choices: TIMs designed to resist pump-out, drying, and filler separation.

- Ease of Application & Reworkability

Easy-to-apply TIMs speed up assembly and make future repairs easier.

Good choices:

- Pads and tapes for clean application.

- Pastes for flexibility.

- Avoid permanent adhesives unless you don’t need to remove them later.

- Compatibility with Device Surfaces & Environment

Some TIMs release vapors that can damage sensors or optical parts.

- Good choices: Materials with low outgassing and that don’t chemically react with your components.

- Mechanical Properties (Hardness, Compression, Thickness)

The TIM must fit the gap and stay in contact under the right pressure.

Good choices:

- Softer pads for better compression.

- Grease or phase-change materials for adjustable fit (but require proper fixtures).

The best TIM isn’t just the one that conducts heat the most. It’s the one that works well with your device, is safe, durable, easy to use, and fits properly.

Categories of Thermal Interface Materials (TIMs)

- Thermal Paste / Grease

Pros:

- Thin layer ensures excellent heat transfer.

- Simple to apply with no curing required.

Cons:

- Can be messy; may separate or “pump out” over time.

- Liquid metal conducts heat well but risks shorting electronics and damaging aluminum.

- Thermal Adhesive

Material that both transfers heat and bonds components together, available as epoxy or adhesive tape.

Pros:

- Offers a strong hold without extra fasteners.

Cons:

- Often needs curing and can be hard to remove.

- It can cause stress from rigid bonding.

- Thermal Gap Filler (Pads & Gels)

Thermal gap fillers (pads & gels) are soft silicone-based materials that fill large or uneven gaps.

Pros:

- Works well on non-flat or thick interfaces.

- Reusable or easy to rework, with less mess.

Cons:

- Lower heat transfer compared to paste.

- May need more compression for best performance.

- Thermal Pads / Tapes

Solid or semi-solid sheets, like silicone pads or adhesive tapes, are placed between components.

Pros:

- Clean, quick to apply; adhesive versions eliminate screws or clamps.

Cons:

- Generally thicker, which reduces thermal efficiency.

- Phase-Change Material (PCM)

Solid at room temperature but softens/melts at operating temperatures, improving surface contact.

Pros:

- Clean handling, stable in place, performs like paste when hot.

- Less prone to pump-out.

Cons:

- More expensive.

- Needs correct pressure and temperature control during use.

- Metal TIM (e.g., Sintered Silver, Indium Alloy)

Highly conductive metallic materials that minimize thermal resistance between surfaces.

Pros:

- Excellent conductivity and less affected by surface flatness or thickness.

Cons:

- Expensive.

- May require special equipment or pressure to install.

- Advanced Materials (Graphite, Pyrolytic Carbon, Nanocomposites)

Next-generation TIMs are made from advanced materials such as graphite, graphene, pyrolytic carbon, or boron nitride.

Pros:

- Can direct heat flow in specific directions (anisotropic).

- Flexible and lightweight; potential for high insulation.

Cons:

- This is a new option, and its price and availability can change.

The right TIM balances performance and practicality based on heat transfer, surface fit, assembly, cost, and maintenance.

Application-Specific Recommendations

- Consumer Electronics (Laptops, Desktops)

- Best TIMs: Thermal pastes, phase-change pads.

- Why: These materials conduct heat well and conform to surfaces, efficiently moving heat from CPUs or GPUs to heatsinks.

- High-Performance Computing (Servers, Gaming PCs)

- Best TIMs: Liquid metal compounds, high-end thermal greases.

- Why: Liquid metals offer excellent heat transfer for high-power components; premium greases are easier to apply and reliable.

- Mobile Devices (Smartphones, Tablets)

- Best TIMs: Phase-change materials (PCMs), ultra-thin thermal pads.

- Why: PCMs adjust to temperature changes, improving thermal management. Thin pads fit tight spaces while transferring heat effectively.

- Automotive & Power Electronics

- Best TIMs: Gap fillers, adhesive pads.

- Why: Fill larger gaps and provide mechanical support, important for power modules, inverters, and batteries.

- LED Lighting & Industrial Equipment

- Best TIMs: Thermal tapes, gels, durable pads.

- Why: To control heat in high-brightness LEDs and industrial machines, protecting components and extending their lifespan.

Pick a TIM that matches your device’s heat, gap, electrical, and environmental requirements for reliable cooling.

Key Tips for Choosing the Right Thermal Interface Material (TIM)

- Understand Thermal Needs

When choosing a TIM, consider the gap between surfaces:

- Thin gaps: For thin gaps, ensure good surface contact and use thermal pastes or PCMs for effective heat transfer.

- Thicker or uneven gaps: Use materials with high thermal conductivity, such as pads or gap fillers, to effectively transfer heat.

- Match Mechanical & Structural Requirements

To match mechanical and structural needs:

Surface shape:

- Flat → thin grease or adhesive films.

- Irregular → soft gels or gap fillers.

Pressure needed:

- Solid pads require more force to fill gaps.

- Greases or PCMs adjust with less pressure.

- Consider Electrical Properties

If you need electrical insulation, use ceramic pastes, silicone pads, or PCMs. Avoid conductive materials like liquid metals or graphite unless conduction is intended.

- Check Environmental & Longevity Factors

Select TIMs that are durable, thermally stable, and fully compatible with surrounding materials. This ensures they don’t dry out, get pushed out, cause corrosion, or release gases.

- Evaluate Application & Maintenance

Pads and adhesive sheets are simpler to use than greases. Consider rework needs and keep surfaces clean for optimal performance.

- Balance Cost and Production Needs

Choose a TIM that balances cost, ease of use, and cooling efficiency.

The best TIM is one that works well, lasts long, and is easy to use, while matching your device’s heat, shape, and electrical requirements.